Meier Medical

High-precision custom metal stamping for medical

High-precision custom metal stamping for medical

Custom Metal Stamping and Precision Parts for Medical Devices

For more than 30 years, Meier Tool has mastered close-tolerance high-precision manufacturing for mission critical systems and has become a premier contract and sub-assembly manufacturer. We offer a powerful portfolio of stamping production capability customized for even the most exacting engineering tolerances. Our expertise includes CAD software design implementation, machining and metal injection molding conversions, and high-precision prototype manufacturing. Our skill, along with our suite of technologies, makes Meier a leader in extremely close-tolerance, mission-critical, sub-assembly production.

Meier has a proven track record of providing medical device manufacturers with significant cost savings by converting from more expensive processes like metal injection molding and machining to lower-cost progressive metal stampings.

Our facilities include an industry-leading validation process that takes micro stamping and metal stamping to the next level. Meier brings a level of operational excellence that has solidified our pioneering status in contract manufacturing, for example, we’ve earned our TUV certification, the gold standard in the industry for decades.

Our fully validated quality systems, complete in-house capabilities, timely investments in cutting-edge technologies and innovative solutions to the most challenging components have made Meier a world leader in stamping precision medical components.

Miniaturization and Cost-Saving Conversions

Meier has applied its expertise to meet the demands of its customers in the medical device industry by providing complex metal stamped components, cost-reducing conversions and innovative technologies.

Medical device innovations continue to push the boundaries of size and scale, seeking to increase the performance and functionality while reducing invasive footprints. At Meier, we take these challenges in stride, applying our design and manufacturing expertise to the demands of part miniaturization.

Our custom metal stamping can produce quality sub-assembly on a range of different metal densities, including aluminum, stainless steel, and copper. With a 35,000 square foot state-of-the-art facility, Meier has high capacity for orders ranging from small batch to hundreds of thousands of units with tolerances as high as .0005.

Cost reductions are critical in meeting the market challenges of reduced reimbursement and competitive advantage. Meier is a leader in helping customers convert their existing component designs from traditional higher-cost manufacturing processes to lower-cost metal stamping when creating complex sub-assemblies from a prototype.

close {x}

Implantable Devices and Components

Hearing Devices

Disposable Devices and Components

close {x}

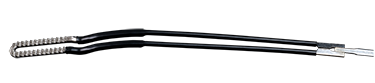

Market: Electrosurgery

Application: Grasping Forceps

Material: Stainless Steel

Material Thickness: Dual Gauge

Complexity: High

Secondary Operations: Wire EDM machining, laser welding, insulation

Conversion from a more costly machining process

Conversion from a more costly machining processMarket: Endoscopy

Application: Biopsy Jaw

Material: Stainless Steel

Material Thickness: .007”

Complexity: High

Secondary Operations: Tumble de-burr and passivate

Market: Endoscopy

Market: Endoscopy

Application: Biopsy Needle

Material: 17-7

Material Thickness: .005”

Complexity: Medium

Secondary Operations: Passivation

Market: Neurostimulation

Application: Electrode

Material: Platinum

Complexity: Medium

close {x}

We are a part of the Cretex family of medical companies, a privately owned enterprise with a proud 100-year history. We offer a complete range of medical device manufacturing expertise and bring you the convenience of billing simplicity, no markups and faster decision-making. We also have the financial strength and resources you may need to match your latest manufacturing technology needs.

By bringing the best together through technology and talent, Cretex Medical can offer a broad range of solutions with capabilities that include:

![]()

![]()

![]()

![]()

close {x}